Roller Track Installation – Common Mistakes and Proven Ways to Avoid Them

Roller tracks, also known as roller rails, are essential components of internal transport systems, enabling the swift and safe movement of goods in production and logistics processes. Due to their versatility, they are used in various industries, such as food processing, logistics, and industrial manufacturing. Selecting the right roller tracks or roller rails and ensuring their professional installation can significantly impact the efficiency and longevity of your transport system.

Although the installation of gravity roller tracks often seems intuitive, there are numerous technical details to consider to avoid problems and extend the durability of these components. This article is aimed at individuals responsible for overseeing production lines, maintaining machinery, and managing maintenance processes within companies. Here, we present practical tips to help you avoid common mistakes during the installation of transport rollers, thereby maximizing their efficiency and reliability.

Key technical aspects to consider when installing roller tracks

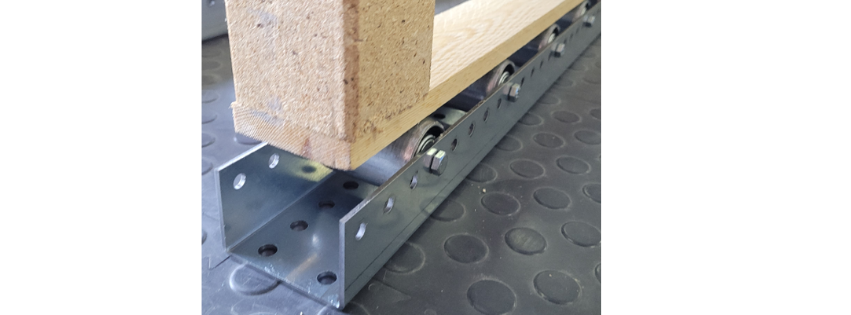

During the installation of gravity roller tracks, certain technical solutions are crucial to ensure the stability and efficiency of the entire transport system. The structure must be solid and precisely leveled, whether the roller tracks are mounted on the floor (such as pallet roller tracks), on shelves, conveyors, or as side barriers.

Our range also includes roller side barriers, ideal for conveyors or transporters, which provide extra protection when transporting goods like windows, PET or glass bottles, jars, and other items requiring lateral guidance.

In our assortment, you will also find various roller track accessories: roller track clips, connector tracks, brake belts, reinforcing clips, roller track brackets, end caps, separators, flat bars, mounting angles, and many other components supporting the installation of transport rollers. These accessories enable the creation of a durable and reliable transport system. Additionally, with each product on our store, you will find a short installation guide (check the attachments) that facilitates mounting on a base, shelf, rack, or frame.

Precise alignment of transport tracks is essential for a smooth product flow. The tracks we supply come fully assembled and ready for installation. Proper leveling relative to the surface is key, allowing gravity to move goods smoothly without friction or jams. For longer roller tracks or greater loads, consider adding additional support points to prevent excessive tension and evenly distribute the weight of the goods. For systems requiring curves, we recommend flexible roller tracks, which easily adapt to bends and more complex transport paths.

If you have any questions or need assistance selecting suitable transport rollers or roller track accessories, our specialists are at your disposal – contact us at +48 500-111-221.

How to care for roller tracks? Inspections and maintenance for maximum durability

Regular inspections of roller tracks are a crucial part of their maintenance, keeping the transport system in optimal condition and preventing premature wear. Early detection of even minor issues, such as loose fittings or signs of wear, allows for quick repairs, which extends the lifespan of roller tracks and helps avoid costly downtime.

Cleaning roller tracks is equally essential for maintenance. Dust, dirt, and other contaminants can accumulate on rollers, creating resistance and slowing down transport. Regular cleaning not only improves the performance of rollers but also reduces the risk of excessive wear, allowing for prolonged, trouble-free operation. If easy cleaning is a priority, consider inverted roller tracks designed to quickly and effectively remove debris and dirt.

Summary

Proper installation of roller tracks on the floor, table, or frame brings numerous benefits to users and teams responsible for maintaining internal transport systems. Professionally installed transport rollers increase work efficiency – goods move smoothly without risk of jams or damage. A solid installation also enhances safety, minimizing the risk of breakdowns and protecting both transported goods and staff. Additionally, a well-designed system helps reduce operating costs, lowering the need for repairs and extending the lifespan of components.

If you are looking for reliable roller tracks tailored to your needs, contact us at +48 61 653 25 60 or write to us at info@construktor.com. We provide expert advice and comprehensive support.