How can roller tracks improve warehouse safety? 4 proven methods

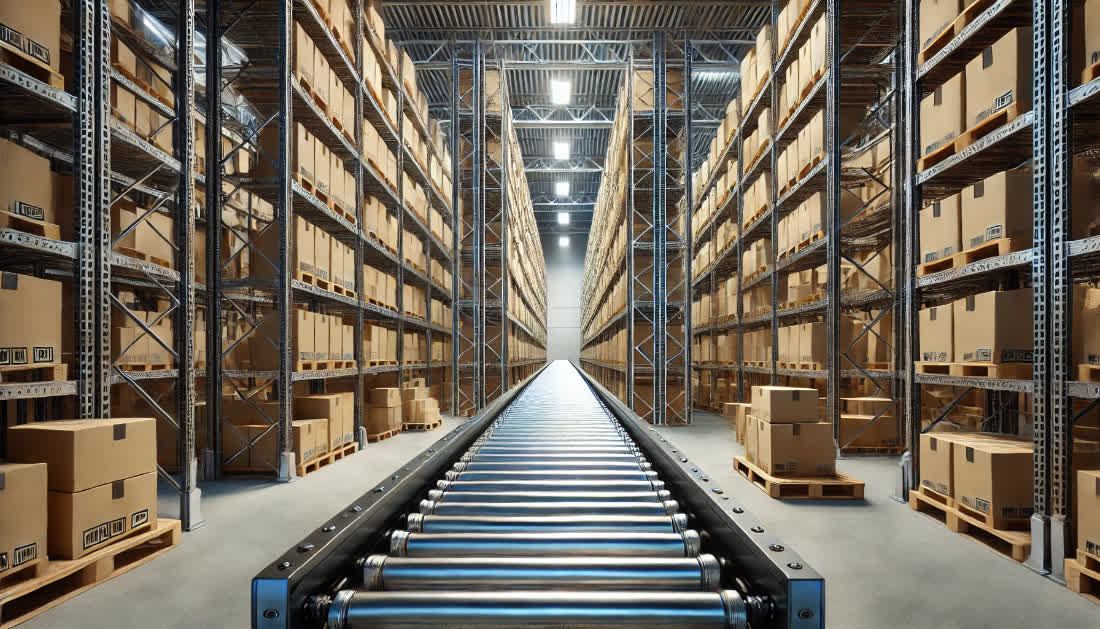

Warehouse safety is a crucial aspect for every company involved in logistics and production. Gravity roller tracks are one of the practical solutions that can effectively help ensure a safe working environment. They facilitate the organization and transport of goods, minimizing the risk of accidents and enhancing the comfort of the team. In this article, we present four proven ways to use roller tracks that can improve safety and order in the warehouse, regardless of the types of products being stored.

- Roller tracks as support for transporting heavy loads

Handling heavy loads in a warehouse is a demanding task, especially regarding safety and ergonomic working conditions. Roller tracks provide an ideal solution that relieves workers from the need to lift goods manually. With our roller tracks, moving loads over short distances becomes easy and nearly effortless. Instead of lifting, employees can slide goods along pallet roller tracks designed for heavy products, reducing the risk of back injuries and strain. Gravity roller tracks, therefore, not only improve efficiency but also safety, facilitating smooth goods flow in the warehouse. Our wide range of conveyor rails ensures an ideal fit for handling heavy goods.

- Roller tracks as a solution to improve warehouse space organization

The proper placement of roller tracks in a warehouse supports optimal space utilization, leading to increased work safety. Well-positioned tracks allow for the creation of transport routes that facilitate a smooth flow of goods and better space management. Roller tracks help organize the warehouse layout, improving visibility, easier access to goods, and reducing the risk of accidents. When planning transport routes, consider using specialized roller tracks, such as curved, swivel, modular tracks, along with the necessary accessories. A well-organized space not only enhances safety but also increases work comfort, supporting the efficiency of the entire warehouse team.

- Preventing accidents during unloading with roller tracks

Gravity roller tracks effectively reduce the risk of collisions and accidents during the unloading of goods by providing smooth, stable movement and eliminating sudden shifts that could lead to accidents. However, selecting the appropriate type of conveyor track for the load’s weight, size, and specific characteristics is essential to avoid overloads and ensure safety. Our specialists will inquire about your warehouse's transport specifics to recommend the optimal solution — from flanged roller tracks, stainless steel, antistatic options, to tracks with rubberized rollers. This way, our conveyor tracks will be precisely tailored to your warehouse’s needs, supporting safe and efficient load handling.

- The role of roller tracks in automating warehouse processes

Warehouse automation sets the course for the future of logistics, and gravity roller tracks play a crucial role in this transformation. They enable seamless load movement in coordination with automated systems, significantly enhancing operational efficiency and safety. Roller tracks minimize the need for manual tasks, often associated with injury risks, while operating solely on gravity, without requiring electric power. Automatic load movement on conveyor lines optimizes processes and allows for better use of available warehouse space. As a result, roller tracks contribute to reducing accidents, improving work efficiency, and shortening order fulfillment times.

In summary

Roller tracks are a simple yet highly effective solution that significantly enhances warehouse safety and work efficiency. We continually refine them and introduce new functionalities, making load transport easier, space organization more intuitive, and automation processes easier to implement. Choosing the right roller track tailored to the warehouse’s needs helps reduce overloads and accident risks, fostering safe working conditions for the team. If you aim to increase safety and efficiency in your warehouse, contact our specialists at +48 61 653 25 60 — together, we will find the best solutions tailored to your requirements.